Unlocking Innovation with Stratasys: The Future of 3D Printing in Business

In today's rapidly evolving technological landscape, Stratasys has established itself as a trailblazer in the world of 3D printing, revolutionizing how businesses approach design, prototyping, and manufacturing processes. As a leader in additive manufacturing, Stratasys offers innovative solutions that enable companies to elevate their innovation capabilities, streamline production, and achieve unprecedented levels of precision and flexibility.

The Evolution of 3D Printing and the Rise of Stratasys

The journey of 3D printing, also known as additive manufacturing, has transformed from a niche technology into a critical component of modern industry. Since its inception, the technology has continually advanced, with Stratasys playing a pivotal role in making 3D printing accessible, reliable, and scalable for enterprise applications. Through pioneering research and development, Stratasys has developed a diverse portfolio of 3D printers, materials, and software solutions that empower businesses across various sectors.

Historical Milestones and Industry Leadership

- Established as a pioneer in fused deposition modeling (FDM) and PolyJet technologies.

- Introduced high-performance materials suitable for functional prototypes and end-use parts.

- Expanded global reach with a comprehensive ecosystem of solutions tailored for industry-specific needs.

- Consistently invested in R&D to push technological boundaries, ensuring top-tier performance and quality.

The Core Technologies of Stratasys and Their Impact on Business

Stratasys specializes in several groundbreaking additive manufacturing technologies, each offering unique advantages essential for different business applications. The two primary methods—Fused Deposition Modeling (FDM) and PolyJet printing—are widely adopted due to their versatility, high precision, and material diversity.

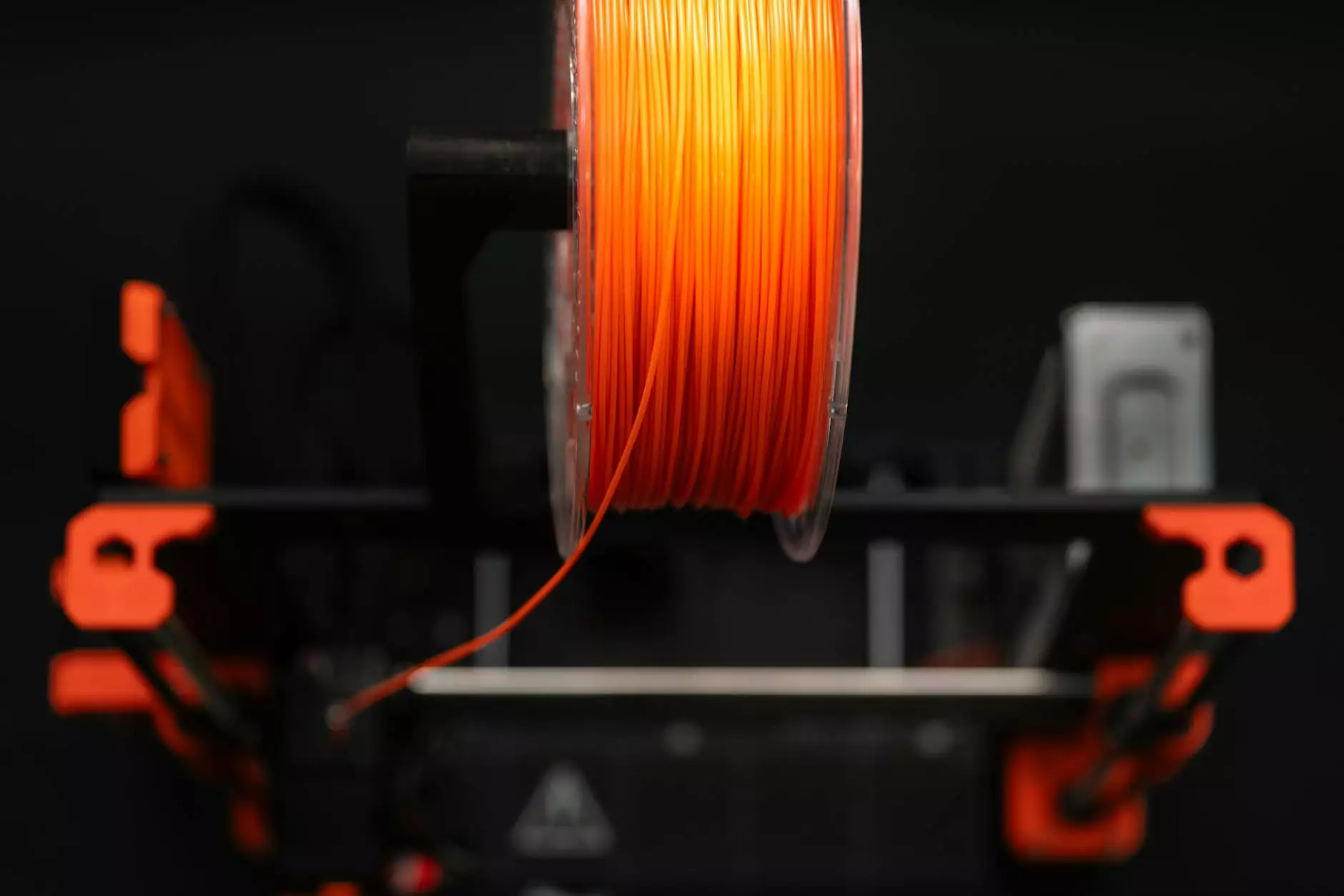

Fused Deposition Modeling (FDM): Building Robust Prototypes and End-Use Parts

FDM technology involves extruding thermoplastic filaments layer-by-layer to create durable, functional parts. This process offers advantages such as high strength, cost-effectiveness, and suitability for producing complex geometries. Businesses leverage FDM for rapid prototyping, tooling, and even small-batch manufacturing of end-use components.

PolyJet Technology: Achieving Detailed, Multi-Material Prints

PolyJet employs jetting of liquid photopolymers to produce highly detailed, smooth-surfaced models that can incorporate multiple materials and colors in a single print. This technology excels in creating realistic prototypes, visual models, and medical devices, enabling designers and engineers to simulate final products with exceptional accuracy.

Agility and Customization with a Broad Material Portfolio

One of the key strengths of Stratasys lies in its extensive library of specialized materials, including flexible, rigid, bio-compatible, high-temperature, and composite options. This diversity allows businesses to tailor their manufacturing processes precisely to their needs, fostering innovation and reducing time-to-market.

How Stratasys Is Transforming Business Operations Across Industries

Across various sectors, Stratasys solutions have become indispensable for improving efficiency, reducing costs, and accelerating innovation. From aerospace to healthcare, automotive to consumer products, the impact of Stratasys technology is profound and far-reaching.

Manufacturing and Automotive

In manufacturing, Stratasys offers rapid prototyping and tooling solutions, allowing automotive companies to iterate designs quickly. The ability to produce functional parts with complex geometries facilitates testing and validation processes, significantly shortening product development cycles and reducing expenses.

Aerospace and Defense

The aerospace industry benefits from the high-performance materials and precision of Stratasys systems, enabling the creation of lightweight, durable components. These solutions help manufacturers meet strict safety and quality standards while improving overall operational efficiency.

Healthcare and Medical Devices

In healthcare, Stratasys provides biocompatible materials for producing surgical models, implants, and prosthetics. The ability to customize devices with high accuracy enhances patient treatment outcomes and supports more personalized medicine.

Consumer Products and Design

Designers and innovators utilize Stratasys printers to create realistic prototypes, mockups, and aesthetic components. This rapid iteration capability accelerates product development timelines, enabling brands to stay ahead of market trends.

The Strategic Advantages of Partnering with Stratasys and Infotron

For businesses seeking to embrace the future of manufacturing, partnering with the right provider is essential. Infotron, as a trusted distributor and solutions provider for Stratasys in Turkey, offers comprehensive support, from consultation to implementation. Collaborating with Infotron ensures access to cutting-edge technology, expert guidance, and tailored solutions that align with your unique business objectives.

Comprehensive Support and Consulting

Our team of experts provides in-depth analysis of your operational needs, recommending the most suitable Stratasys systems and materials. We assist in strategic planning, installation, and staff training, ensuring your organization maximizes investment return.

Customized Solutions for Diverse Industries

Whether you're in aerospace, automotive, healthcare, or design, Infotron offers specialized solutions that meet your industry standards and requirements. Our focus is on delivering scalable and adaptable 3D printing setups that grow with your business.

Ongoing Maintenance and Support

We understand that technological infrastructure requires ongoing care. Our service plans include maintenance, upgrades, and technical support to ensure your Stratasys systems operate at peak efficiency, minimizing downtime and maximizing output.

Future Trends and the Role of Stratasys in Industry 4.0

The dawn of Industry 4.0 heralds a new era of interconnected, intelligent manufacturing processes. Stratasys is actively shaping this future through innovations such as multi-material printing, advanced software integration, and scalable production platforms. These advancements will provide businesses with unparalleled flexibility, customization, and speed in their manufacturing workflows.

Additionally, the integration of 3D printing with digital supply chains and smart factories will enable real-time production adjustments, reduce waste, and facilitate just-in-time manufacturing. Embracing Stratasys solutions positions companies at the forefront of these transformative trends, ensuring competitiveness and sustained growth.

Why Choose Stratasys? Key Differentiators for Business Success

- Technological Leadership: Continuous innovation and high-quality solutions tailored for industrial use.

- Material Diversity: An extensive portfolio allowing creation of functional, aesthetic, and specialized components.

- Global Support Network: Extensive customer service and technical support to ensure seamless integration and operation.

- Sustainable Manufacturing: Eco-friendly materials and processes that reduce waste and energy consumption.

- Cost Efficiency: Lower prototyping and production costs compared to traditional manufacturing methods.

- Customization and Scalability: Solutions adaptable to evolving business needs, from small prototypes to high-volume production.

Take Your Business to the Next Level with Stratasys and Infotron

In an era where innovation and efficiency dictate market success, leveraging advanced 3D printing technologies such as those offered by Stratasys is more critical than ever. Through strategic partnerships with trusted providers like Infotron, your business can harness the full potential of additive manufacturing, gain a competitive edge, and accelerate growth.

Embrace the future of manufacturing—invest in Stratasys solutions today and unlock your company's innovative capacity.